Types of relays Introduction of several commonly used relays

Generally speaking, there are three types of relays we use most often: general purpose relays, control relays and protective relays.

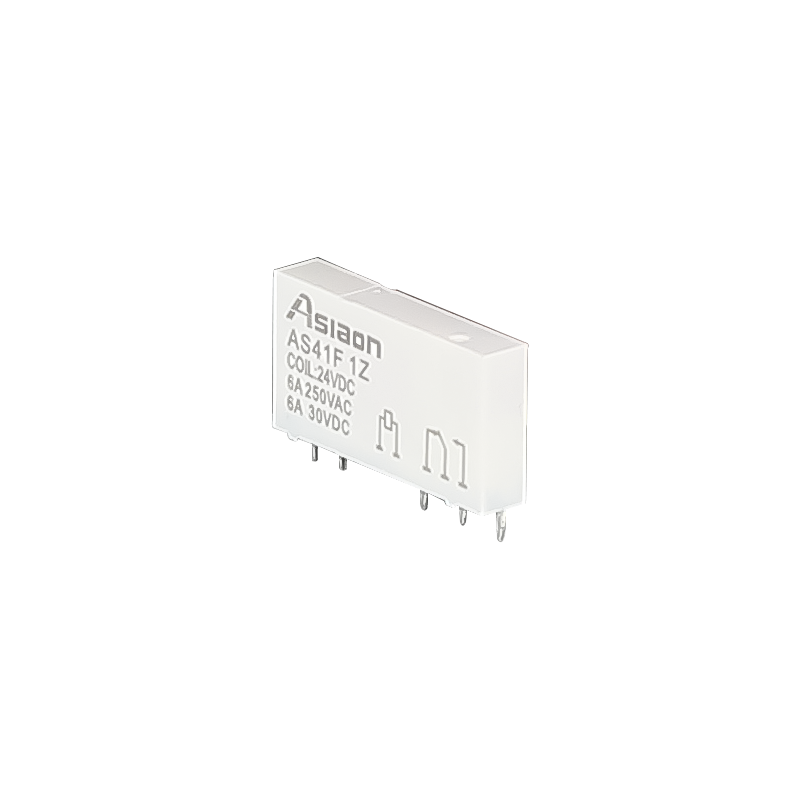

These relays are divided into electromagnetic relays and solid-state relays, which have protection and switching functions. First of all, as a general-purpose relay, the electromagnetic relay has only one coil, and as long as the coil is energized, a magnetic field will be generated. Thus, the electrical armature of the relay will be attracted by this magnetic field, which will promote its action and will also drive the contacts of the relay to operate.

In addition, another general-purpose relay is the solid-state relay, which is somewhat different from the electromagnetic relay. This type of relay is a contactless switch with an electronic circuit inside. As shown in the diagram below, we can clearly see that one section of the relay is the input and the other end is the output. In fact, the output is a switch and we can adjust the input by some methods to achieve the purpose of switching the output.

2. Control Relay

Among the common types of such relays we have are: pressure relays, intermediate relays, express relays, etc. Next, we will explain these relays one by one. Among these relays, intermediate relays are the most widely used because they function to control the load directly. Besides that, it can also indirectly control high power loads with AC contactors.

Time relays among control relays are usually used in delay circuits; speed relays are mainly used as reverse brakes for motors, i.e. when the motor is in braking condition and the speed is almost zero, we can stop the rotation by disconnecting the power switch; pressure relays, as the name suggests, are related to pressure and their function is to sense pressure. When the pressure of the liquid reaches the set value, the contacts of the relay will move.

3. the protection relay

This kind of relay belongs to the protection component, which can be divided into overload relay, temperature relay, voltage, current relay, etc. It is not difficult to understand what is a protective component relay, that is, the relay can be controlled by the temperature, voltage and other factors of the state and worthy of change.

For example, in the case of a thermal relay, when the motor is overloaded, it is already much larger than the set rectification value. Thus, the high current in the thermal element deforms it by overheating and breaks the contacts, thus cutting off the circuit and preventing the fault from expanding. After cooling for some time, the deformation itself will slowly reset and the circuit will close. Of course there is a manual reset and automatic reset, to adjust themselves according to the specific situation.

Several commonly used relays are introduced

1、Electromagnetic relay

Principle of operation.

With a smaller current or voltage to control a larger current or voltage of a "automatic switch.

2, voltage relay

Principle of operation.

Used to increase the number of signals in the control circuit or signal amplification, is a fixed action value and release value of the voltage relay.

3, time relay

Principle of operation.

Internal sensing mechanism to receive external action signal, after a period of delayed contact action or output circuit to produce a jump change in the relay.

4、Pressure relay

Principle of operation.

According to the change of pressure to determine the contact opening and breaking, convenient to provide control and protection of mechanical equipment.

5、Thermal relay

Working principle.

Electrical protection components, the use of the thermal effect of current to drive the internal action mechanism to close or break the contacts of the protection apparatus.

6、Over-voltage relay

Principle of operation.

According to the voltage value and the size of the action of the relay, when the input voltage value reaches the set voltage, its contacts will make the corresponding action.

中文

中文 Русский

Русский Español

Español