The difference between conventional relays and power relays

All electrical devices need to be switched at some point in their operation; after all, they can't be left on forever. These electrical devices may range from low-power devices such as light bulbs to high-power devices such as motors, automotive electronics, and elevators. But just like all other electronic components, relays have some limitations. They have a maximum allowable power rating for each model and variant.

For example, if a common relay rated at 60W is supplied with 250V and the load draws a current of 2A, problems will arise. The power consumed can be calculated as the product of the applied voltage and the current consumed by the relay, calculated as 500W, which is more than a multiple of the actual power rating of the relay. This can permanently damage the relay.

Another major problem affecting relay performance when operating at high voltage is arc discharge. It is the flow of current from one contact of the relay to the other, through the air gap that exists between them while they are open. Arcing generates a lot of internal heat and over time also corrodes the contacts, thus shortening the life of the relay.

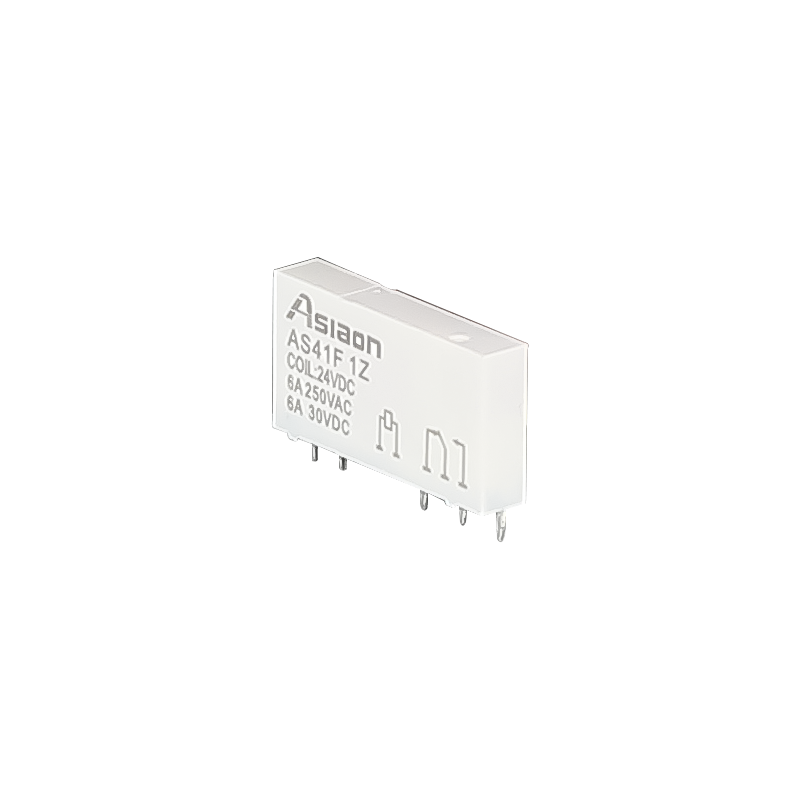

In order to meet such high current and voltage requirements without exceeding power and temperature thresholds, power relays are used. Power relays operate on the same principle as ordinary relays. They have the same components and the same switching methods as described above, but they have higher current and voltage ratings, enabling switching to be performed on high power loads. Unlike conventional relays, power relays are specially designed to generate less heat and reduce arcing during switching. The switching contacts of a power relay are very different from those of a conventional relay.

Power is proportional to resistance, so increasing resistance increases the power consumed. The switching contact also has a certain resistance, which is determined by the material it is made of. One way to reduce the amount of heat generated is to carefully select the material of the switching contacts so that they have a low resistance. This reduces power consumption and keeps the relay in safe operating conditions.

Conventional relays should be selected for low power signals. They can be used for small electronic applications, hobbyist projects involving microcontrollers, etc. On the other hand, power relays should be selected for power switching industrial applications such as automotive, elevators, and operating valves.

Choosing the right relay is critical to the reliability of the controller and the integrity of the switching signal. Before selecting a relay, you should consider not only the power rating, but also other important factors such as its operating life, operating environment, size, coil voltage, coil current, and switching time. All of these factors play an important role in making your system more efficient and safer.

中文

中文 Русский

Русский Español

Español