Introduction to general purpose relays, control relays and protective relays

As one of our common switching devices, relays belong to the category of controllable switches. Relays have a wide range of applications, especially in electrical control. Since there are more than one or two types of relays, they are sometimes often confused, so let's learn about the various relays together next.

In general, there are three types of relays that we use most often: general purpose relays, control relays, and protective relays.

General purpose relays

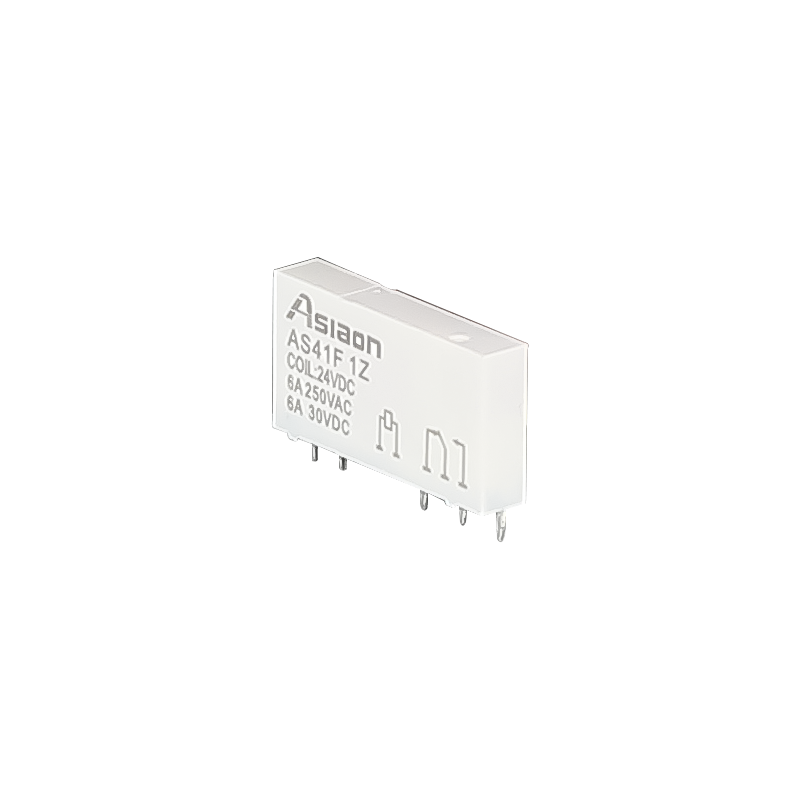

These relays are divided into electromagnetic relays and solid-state relays, which have the role and function of protection, but also have the role of switching. Let's start with the first type, as a general-purpose relay, electromagnetic relays are simply a coil, and this coil will generate a magnetic field as soon as it is energized.

In this way, the armature of the relay is attracted to the magnetic field, which drives its action and also drives the contacts of the relay. Often electromagnetic relays can bring about the following effects: normally open contacts close and normally closed contacts break. When there is no current passing through the coil, the armature of the relay will automatically return to its original state under the action of the spring, which means that both the normally open and normally closed contacts will be reset.

In addition, there is a general-purpose relay is a solid-state relay, which is a little different from the electromagnetic relay, this type of relay is a non-contact switch, and the internal is an electronic circuit. The output is a switch, we can achieve the purpose of the output on and off by some methods, this method is to adjust the input.

Control Relay

This kind of relays in our common types are: pressure relay, intermediate relay, courier relay, time relay, etc.. Among these relays, the most widely used one is the intermediate relay, because its function is to control the load directly. In addition to this role, it can also control AC contactors to indirectly control high power loads.

The time relay in the control relay is usually used to delay the circuit; speed relay is mainly used as a motor reverse braking, that is, when the motor is in the braking state and the speed has almost 0, we can make it stop rotating by disconnecting the power switch; pressure relay, as the name implies, is related to pressure, its role is to sense the pressure. After the pressure of the liquid has reached a set value, the contacts of the relay will be activated.

the protection relay

This type of relay belongs to the protective element category, which can be divided into overload relays, temperature relays, voltage and current relays, and so on. It is not difficult to understand what is a protective element type relay, which means that it can control the relay by the state of temperature, voltage and other factors and worthy of change.

For example, in a thermal relay, when the motor is in an overload state, it is already much larger than the set value, so that the high current in the thermal element makes itself overheat and break the contact, thus cutting off the circuit to prevent the expansion of the fault, when cooled for a period of time, its own deformation will slowly reset, the circuit will be closed and conductive again. Of course, there is a manual reset and automatic reset, this should be adjusted according to the specific needs of their own.

中文

中文 Русский

Русский Español

Español