What are the classifications and uses of relays

After more than 100 years of development, relays have formed various forms, such as time relays, temperature relays, reed relays, thermal relays, differential relays, photorelays, sound relays, Hall relays, and now solid state relays. From machinery to electronics, there are various forms, and they are commonly classified into three types: general-purpose relays, control relays, and protection relays.

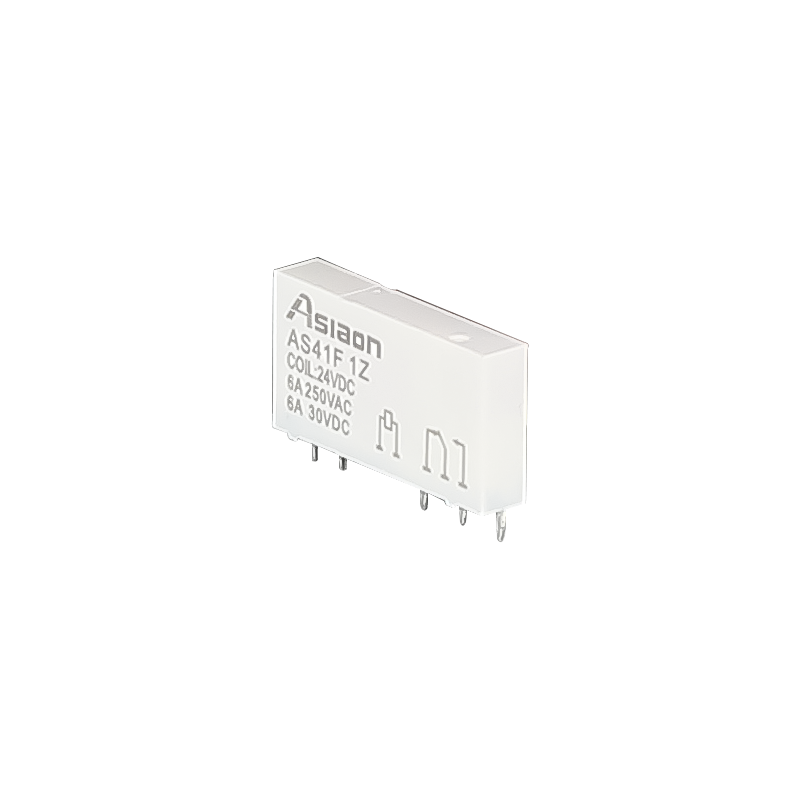

1.First, General Purpose Relays have both the function of a switch and a protection function. The common ones are electromagnetic relays and solid state relays. Electromagnetic relays are actually one type. Electromagnetic relays generally have only one coil. The attraction action drives the contact action. The common effect is: the normally open contact is closed, the normally closed contact is disconnected, when the coil is powered off, the armature is reset under the action of the spring, and the normally open and normally closed contacts are also reset.

2.Common control relays are: intermediate relays, time relays, speed relays, pressure relays, etc. The intermediate relays are the most common, which can directly control the load, and can also control the AC contactor to indirectly control the high-power load. The time relay is generally used in delay circuits , such as the common star-delta step-down start, auto-transformer step-down start, etc. The speed relay is often used for the reverse braking of the motor. When the speed of the motor is close to zero in the braking state, the power supply is cut off and the rotation is stopped. The pressure relay is an induction When the pressure of the liquid reaches the set value, the contact will act.

3.Protection relays include: thermal overload relays, current relays, voltage relays, temperature relays, etc. This type of relay belongs to protection components. It is best to understand that they control the on-off of relays through changes in temperature, voltage, current and other factors. Taking a common thermal relay as an example, when the motor is overloaded, it exceeds the setting value we set, and the large current in the thermal element causes itself to overheat and deform and disconnect the contact, thereby cutting off the circuit to prevent the fault from expanding. , the self-deformation will slowly reset, and the circuit will be closed and turned on again. Of course, there are manual reset and automatic reset, which can be adjusted according to different needs.

中文

中文 Русский

Русский Español

Español